Alfa Laval Industrial line is a wide product range that is used in virtually all types of industry. Designed for high throughput, this model delivers excellent thermal performance. A large selection of plate and gasket types is available.

Applications

- Biotech and Pharmaceutical

- Chemicals

- Energy and Utilities

- Food and Beverages

- Home and Personal care

- Machinery and Manufacturing

- Marine and Transportation

- Mining, Minerals and Pigments

- Pulp and Paper

- Semiconductor and Electronics

- Steel

- Water and Waste treatment

Benefits

- High energy efficiency – low operating cost

- Flexible configuration – heat transfer area can be modified

- Easy to install – compact design

- High serviceability – easy to open for inspection and cleaning and easy to clean by CIP

- Access to Alfa Laval’s global service network

Features

Every detail is carefully designed to ensure optimal performance, maximum uptime and easy maintenance. Selection of available features:

- 5-point alignment system

- Reinforced hanger

- CurveFlowTM distribution area

- Glued gasket

- ClipGripTM gasket

- Leak chamber

- Bearing box

- Fixed bolt head

- Key hole bolt opening

- Lifting lug

- Lining

- Lock washer

- Pressure plate roller

- Swing feet

- Tightening bolt cover

Technical data

Plates

Name: T35-P

Type: Single plate

Free channel, mm (inches): 3.4 (0.13)

Materials

Heat transfer plates: 304/304L, 316/316L, 904L, 254

C-276, C-2000

G-30

Ti, TiPd

Field gaskets: NBR, EPDM, FKM

Flange connections: Carbon steel, Metal lined: stainless steel, Alloy 316, titanium

Frame and pressure plate: Carbon steel, epoxy painted

Other materials may be available on request. All option combinations may not be configurable.

Operational data

Frame, PV-code: FL, pvcALS

Max. design pressure (barg/psig): 6.0/87

Max. design temperature (°C/°F): 100/212

Frame, PV-code: FM, pvcALS

Max. design pressure (barg/psig): 10.3/150

Max. design temperature (°C/°F): 120/248

Frame, PV-code: FM, PED

Max. design pressure (barg/psig): 10.3/150

Max. design temperature (°C/°F): 180/356

Frame, PV-code: FG, pvcALS

Max. design pressure (barg/psig): 16.0/232

Max. design temperature (°C/°F): 180/356

Frame, PV-code: FG, ASME

Max. design pressure (barg/psig): 10.3/150

Max. design temperature (°C/°F): 250/482

Frame, PV-code: FG, PED

Max. design pressure (barg/psig): 16.0/232

Max. design temperature (°C/°F): 180/356

Frame, PV-code: FD, pvcALS

Max. design pressure (barg/psig): 25.0/363

Max. design temperature (°C/°F): 180/356

Frame, PV-code: FD, ASME

Max. design pressure (barg/psig): 20.7/300

Max. design temperature (°C/°F): 250/482

Frame, PV-code: FD, PED

Max. design pressure (barg/psig): 25.0/362

Max. design temperature (°C/°F): 180/356

Frame, PV-code: FS, ASME

Max. design pressure (barg/psig): 27.6/400

Max. design temperature (°C/°F): 250/482

Frame, PV-code: FS, PED

Max. design pressure (barg/psig): 30.0/435

Max. design temperature (°C/°F): 180/356

Extended pressure and temperature rating may be available on request.

Flange connections

FL, pvcALS: EN 1092-1 DN350/DN300 PN10

ASME B16.5 Class 150 NPS 14/NPS 12

JIS B2220 10K 300A/350A

FM, pvcALS: EN 1092-1 DN350/DN300 PN10

ASME B16.5 Class 150 NPS 14/NPS 12

JIS B2220 10K 350A/300A

FM, PED: EN 1092-1 DN350/DN300 PN10

ASME B16.5 Class 150 NPS 14/NPS 12

FG, pvcALS: EN 1092-1 DN350/DN300 PN16

ASME B16.5 Class 150 NPS 14/NPS 12

JIS B2220 16K 350A/300A

FG, ASME: ASME B16.5 Class150 NPS 14/NPS 12

FG, PED: EN 1092-1 DN350/DN300 PN16

ASME B16.5 Class 150 NPS 14/NPS 12

FD, pvcALS: EN 1092-1 DN350/DN300 PN25

ASME B16.5 Class 300 NPS 14/NPS 12

JIS B2220 20K 350A/300A

FD, ASME: ASME B16.5 Class 300 NPS 14/NPS 12

FD, PED: EN 1092-1 DN350/DN300 PN25

ASME B16.5 Class 300 NPS 14/NPS 12

FS, ASME: ASME B16.5 Class 400 NPS 14/NPS 12

Standard EN1092-1 corresponds to GOST 12815-80 and GB/T 9115.

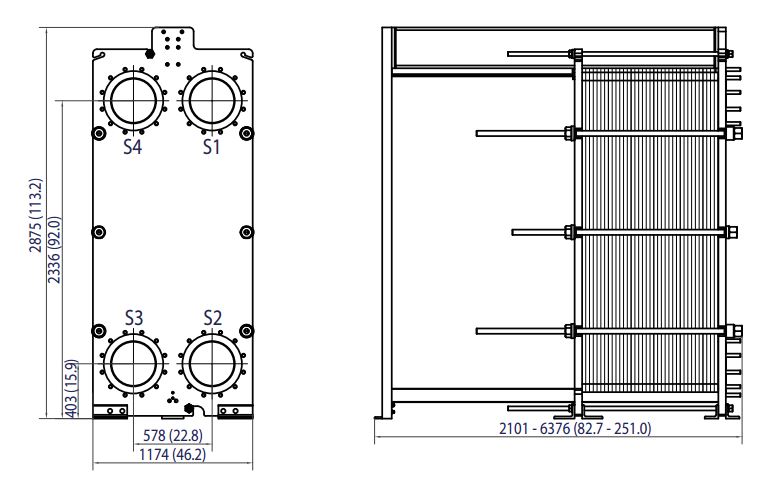

Dimensional drawing

Measurements mm (inches)

The number of tightening bolts may vary depending on pressure rating.