Heat Exchanger Service & Refurbishment

We offer heat exchanger service and refurbishment solutions to customers across the UK and Ireland. Heat exchanger service, maintenance, and testing can take place on your site.

Alternatively, our reconditioning centre, located in Retford, Nottinghamshire, is also able to provide heat exchanger maintenance and restoration solutions. It is also the most modern centre of its kind in the UK's.

Our Heat Exchanger Services

Our experienced and knowledgeable team of engineers can provide the below range of heat exchanger services.

- On and off-site experienced service engineers

- Decommissioning of PHE

- Removal of old gaskets

- Chemically cleaning of plates

- UV crack detection testing

- Gasket grove distortion check

- Oven curing of gaskets to plates

- Commissioning of PHE

- Integrity testing

- Hydrostatic testing

- Complete frame refurbishments

- 24/7 emergency telephone/call out support

- ISO 9001 Certified company

We provide these heat exchanger services to our customers in a range of industries. We're very proud of the work they do each and every day to provide our customers with an honest, straightforward approach. Our goal is to make sure your operations run as smoothly as possible.

SPX Flow Certified Service & Repair Centre

Our heat exchanger service and refurbishment centre have been awarded Certified Service & Refurbishment Centre status by SPX Flow. This official SPX Flow accreditation means we're now certified to service, maintain and refurbish SPX Flow plate heat exchangers. Our facilities and a team of engineers have been SPX Flow verified through a rigorous audit process.

We already have many years of experience and knowledge working with SPX FLOW plate heat exchangers. This official accreditation confirms the work we undertake is carried out to the highest quality standards.

The Heat Exchanger Refurbishment Process

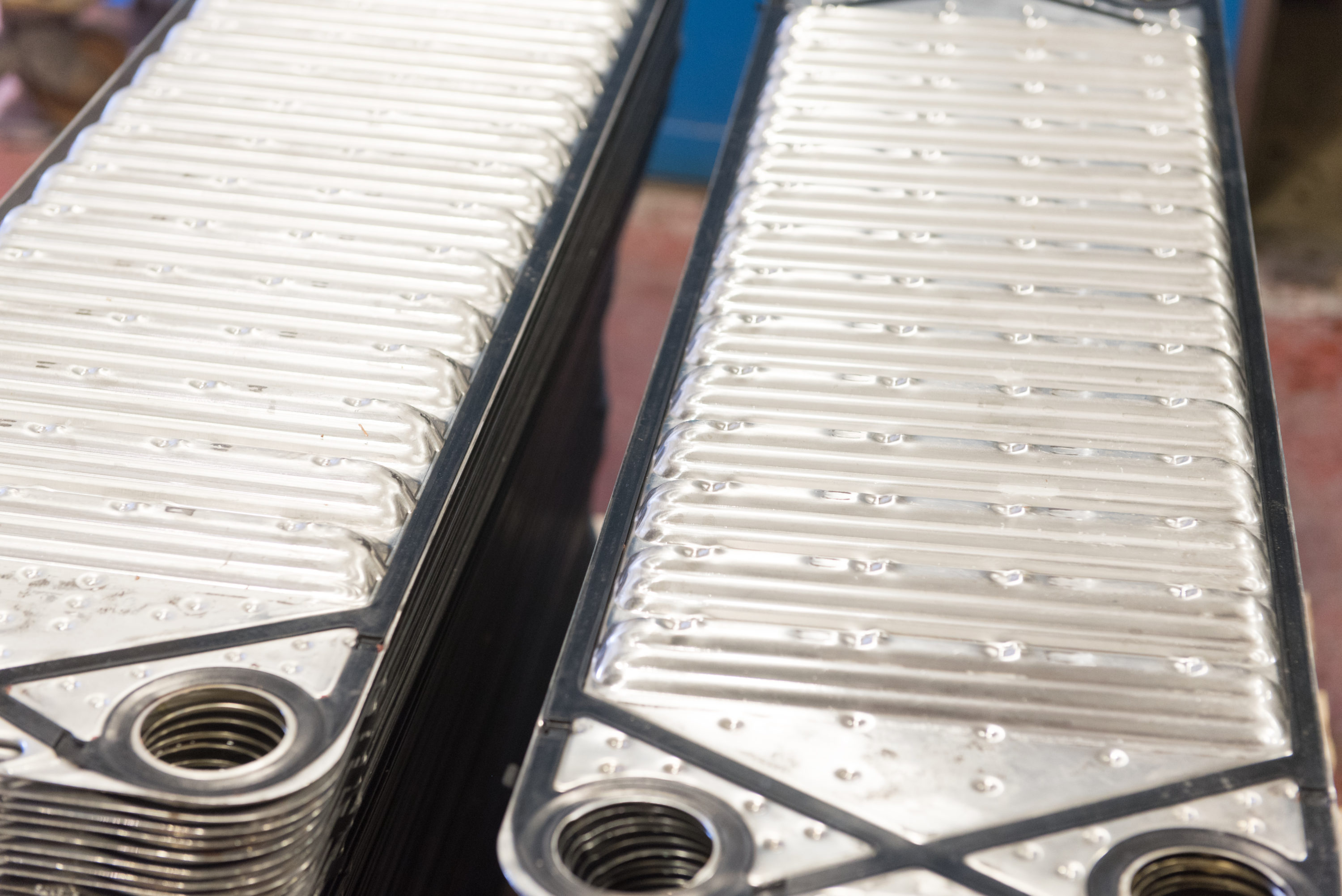

Only to the highest quality are your plate heat exchangers cleaned and tested. The process of plate heat exchanger refurbishment includes the following steps:

1) Identify & Inspect Plates

Once plates arrive for refurbishment they are identified and logged. All gaskets are carefully removed from the plates.

2) Chemical Cleaning

The plates are chemically cleaned. Firstly they are immersed in an alkali bath followed by an acid bath.

3) Rinsed & Dried

Plates are rinsed off with a high-pressure washer and thoroughly dried.

4) Fluorescent Dye Application

Once dried, the plates are individually sprayed with a fluorescent dye penetrant.

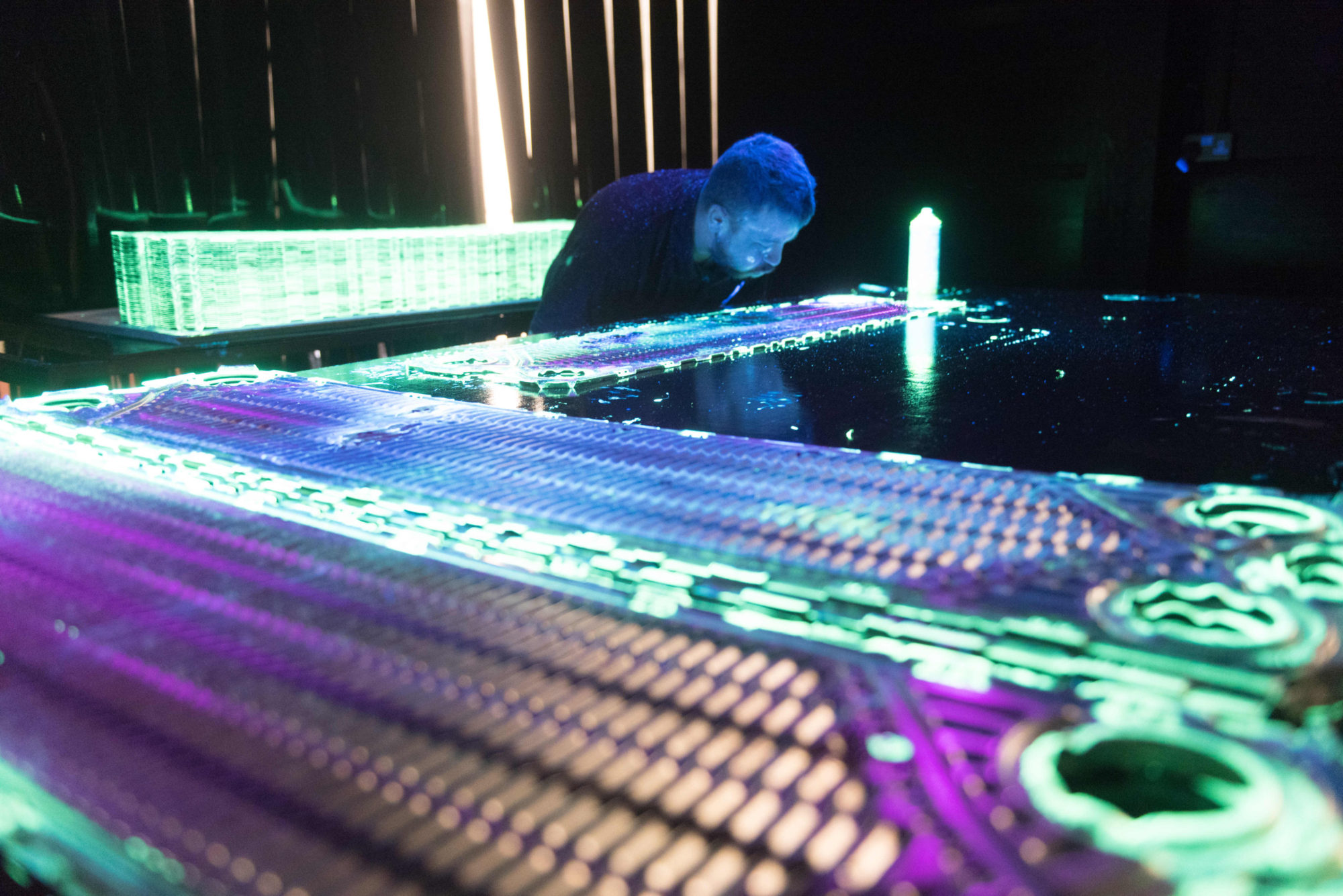

5) Ultraviolet Inspection

Each individual plate undergoes a test using ultraviolet lighting to detect pinholes and fine cracks. Visual inspection also takes place at this stage to identify any wear, pitting, or channel deformation.

6) Gasket & Plate Assembly

Following an inspection, new gaskets are clipped or bonded to the refurbished plates. Appropriate adhesives are used where required. All plates are clamped to ensure correct alignment and if necessary, oven cured.

7) Completing the Process

Finally, the plates undergo a final check to ensure full adhesion and alignment. Plates are repackaged for despatch.

Speed of Response

We understand that for many of our customers, speed of response and reliable service is essential to maintaining production. Our state-of-the-art in-house heat exchanger maintenance and restoration centre is specifically designed to be able to handle a large number of plates at any given time. Furthermore, our large team of dedicated engineers are experienced working to tight deadlines.

Our 24/7 emergency call-out service will also assure you that we can support you in any eventuality.

Book Your Plate Heat Exchanger Refurbishment or Integrity Testing Today.