Alfa Laval Industrial line is a wide product range that is used in virtually all types of industry. The relatively tall plate makes this model suitable for duties with long temperature programs and when high heat recovery is appreciated. A large range of plate and gasket types is available.

Applications

- Biotech and Pharmaceutical

- Chemicals

- Energy and Utilities

- Food and Beverages

- Home and Personal care

- Machinery and Manufacturing

- Marine and Transportation

- Mining, Minerals and Pigments

- Pulp and Paper

- Semiconductor and Electronics

- Steel

- Water and Waste treatment

Benefits

- High energy efficiency – low operating cost

- Flexible configuration – heat transfer area can be modified

- Easy to install – compact design

- High serviceability – easy to open for inspection and cleaning and easy to clean by CIP

- Access to Alfa Laval’s global service network

Features

Every detail is carefully designed to ensure optimal performance, maximum uptime and easy maintenance. Selection of available features:

- 5-point alignment system

- Corner guided alignment system

- Reinforced hanger

- Chocolate pattern distribution area

- Clip-ad gasket

- Leak chamber

- Bearing box

- Fixed bolt head

- Key hole bolt opening

- Lifting lug

- Lining

- Lock washer

- Pressure plate roller

- Tightening bolt cover

Technical data

Plates

Name: TL15-B

Type: Single plate

Free channel, mm (inches): 1.9 (0.075)

Materials

Heat transfer plates: 304/304L, 316/316L, Ti

Field gaskets: NBR, EPDM

Flange connections Carbon steel, Metal lined: stainless steel, titanium, Rubber lined: NBR, EPDM

Frame and pressure plate: Carbon steel, epoxy painted

Other materials may be available on request. All option combinations may not be configurable.

Operational data

Frame, PV-code: FM, pvcALS

Max. design pressure (barg/psig): 10.0/145

Max. design temperature (°C/°F): 180/356

Frame, PV-code: FG, pvcALS

Max. design pressure (barg/psig): 20.0/290

Max. design temperature (°C/°F): 200/392

Frame, PV-code: FG, ASME

Max. design pressure (barg/psig): 10.3/150

Max. design temperature (°C/°F): 250/482

Frame, PV-code: FG, PED

Max. design pressure (barg/psig): 20.0/290

Max. design temperature (°C/°F): 200/392

Frame, PV-code: FD, ASME

Max. design pressure (barg/psig): 20.7/300

Max. design temperature (°C/°F): 250/482

Frame, PV-code: FS, pvcALS

Max. design pressure (barg/psig): 35.5/507

Max. design temperature (°C/°F): 200/392

Frame, PV-code: FS, ASME

Max. design pressure (barg/psig): 31.7/460

Max. design temperature (°C/°F): 250/482

Frame, PV-code: FS, PED

Max. design pressure (barg/psig): 35.0/507

Max. design temperature (°C/°F): 200/392

Extended pressure and temperature rating may be available on request.

Flange connections

FM, pvcALS: EN 1092-1 DN150 PN10

ASME B16.5 Class 150 NPS 6

JIS B2220 10K 150A

FG, pvcALS: EN 1092-1 DN150 PN16

EN 1092-1 DN150 PN25

ASME B16.5 Class 150 NPS 6

JIS B2220 10K 150A

JIS B2220 16K 150A

FG, ASME: ASME B16.5 Class150 NPS 6

FG, PED: EN 1092-1 DN150 PN16

EN 1092-1 DN150 PN25

ASME B16.5 Class 150 NPS 6

FD, ASME: ASME B16.5 Class 300 NPS 6

FS, pvcALS: EN 1092-1 DN150 PN25

EN 1092-1 DN150 PN40

ASME B16.5 Class 400 NPS 6

JIS B2220 10K 150A

JIS B2220 20K 150A

FS, ASME: ASME B16.5 Class 400 NPS 6

FS, PED: EN 1092-1 DN150 PN25

EN 1092-1 DN150 PN40

ASME B16.5 Class 400 NPS 6

Standard EN1092-1 corresponds to GOST 12815-80 and GB/T 9115.

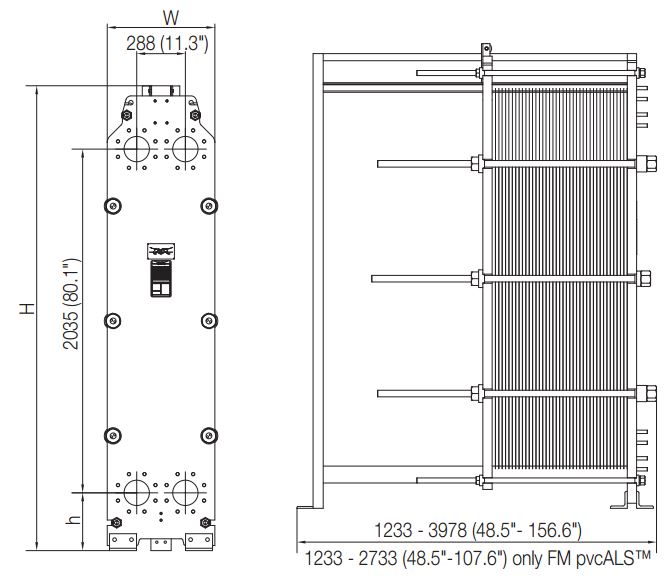

Dimensional drawing

Measurements mm (inches)

Type: TL15-FM

H: 2752 (108.3”)

W: 610 (24.0”)

h: 342 (13.5”)

Type: TL15-FG

H: 2752 (108.3”)

W: 637 (25.1”)

h: 342 (13.5”)

Type: TL15-FG, ASME

H: 2752 (108.3”)

W: 646 (25.4”)

h: 342 (13.5”)

Type: TL15-FD, ASME

H: 2752 (108.3”)

W: 646 (25.4”)

h: 342 (13.5”)

Type: TL15-FG

H: 2752 (108.3”)

W: 646 (25.4”)

h: 342 (13.5”)

Type: TL15-FS, ASME

H: 2752 (108.3”)

W: 646 (25.4”)

h: 342 (13.5”)